Machine Shop In Fremont, CA

A machine shop is a place where components are cut, manufactured, and completed in order for them to be used. Mechanics at machine shop in Fremont, CA utilize machine shops to create new components as well as fix current equipment and parts. Some machining techniques need utmost proficiency level as well as a wide and thorough understanding of the completed goods’ the purpose for which it has been operated. Vehicles, aero planes, big engines, and manufacturing equipment may all be made or maintained at our machine shop in Fremont.

There are several machine shops that have safety rules in place to cope with common Protective equipment such as goggles and face masks must be taught to and required to be worn by workers prior to utilizing the equipment but we at machine shop Fremont, CA deliver safety at all cost to both our workers and customers.

A continual awareness of risks, such as spills or individuals working with hazardous chemicals, is required in the common area. On a regular basis, a safety officer checks the machine shop for indicators of risk. Some high schools have a machine shop that provides vehicle maintenance and repair at our machine shop in Fremont, CA.

A machine shop is generally on-site at these businesses for the manufacturing of new, bespoke, and test components. Individuals learn about machining in educational and research facilities in the context of maintenance and manufacturing components for specific objectives, such as making equipment for use in experiments.

When it comes to the machine operation even the smallest error may have an adverse impact that cannot be taken or waited to even take place. There’s a lot of noise, and some of the machinery emits hazardous chemicals or lacks splash protection. Sharp chips, metallic dust, splinters, and shavings are produced by machines. Some machinery’s design is poor, posing a considerable danger of injury. To replace obsolete equipment, newer equipment must be purchased, as well as upkeep. The first step in enhancing safety is to identify potential risks and poorly designed procedures that might endanger personnel.

Heavy machinery, such as lathes and drill presses, are commonly seen in a Our machine shop Fremont, CA but with utmost care. An appropriate ventilation system, as well as rasps, files, and other tiny finishing equipment, as well as paint booths for painting or coating finished goods, are in place to reduce the danger of particles entering the building. Many businesses rely on robotic systems to produce components that must be maintained clean and free of contamination. Workers outside the room control the robot while it makes a component to specification at our Machine Shop Fremont, CA.

Parts of machine shop in Fremont, CA

Milling machine

A mill is a machine that removes material from a workpiece using rotary cutters. Milling cutters are available in a variety of shapes and sizes, in addition to a variety of sizes and styles, allowing a milling machine to accomplish a variety of tasks.

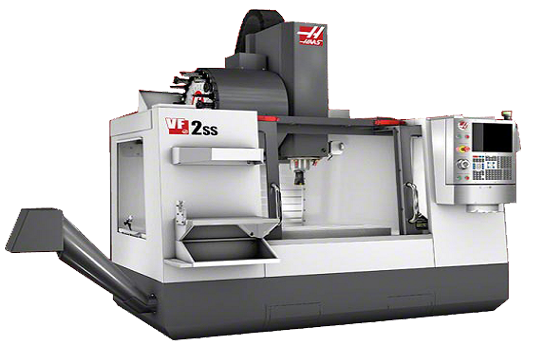

Machining Centre

Machining centres and computer-aided design are two more synonyms for CNC milling machines (CAD). They are multifunctional machines capable of performing complex tasks at high speeds, such as turning and milling.

Lathe

Work components can be spun on a lathe and sanded, knurlled, and faced. The CNC lathe, also known as a CNC turning centre, is controlled by computer instructions.

Grinding Machine

Grinders utilise an abrasive wheel to grind a workpiece. Because of its excellent surface quality, grinding is widely employed as a metal finishing technique.

Drill Press

A mounted drill with a lever-controlled drill press is one kind amongst many in a mounted drill. Drill presses are a more powerful and dependable alternative to handled drills for a variety of industrial activities, including drilling holes.

Bandsaw

As the name implies, a bandsaw is a multi-purpose cutting instrument that may be used for a number of applications. It is used to remove small amounts of material in preparation for more precise cutting.

EDM Equipment

Instead of using a physical cut-off tool that uses sparks, electrical discharge machining (EDM) is utilised to pierce the workpiece. Some variations of the tool electrode don’t need a wire at all.

Surface Finishing Tools

Most components require a variety of tools to polish, sandblast, and colour.

Coordinate Measuring Machine

As part of the machining process, a Coordinate Measurement Machine (CMM) is used to match an item’s geometry.

You won’t have to look for another machine shop in the future if you choose a business that offers a wide range of services the way our machine shop Fremont, CA will provide you. Be sure you choose a business partner that has the required equipment, expertise, and abilities, as well as a dedication too like we provide.